From planning to implementation – everything from a single source

Whether you have questions about process development, process optimization, programming or the general improvement of product quality and efficiency: we provide you with full support for your project. Our wide range of services includes engineering services for ECM, PECM, laser and cleaning technology as well as automation. Our experts will support you from the analysis to the conception phase of a project, from prototype development to production optimization. And always with a focus on the common goal.

Design and programming

In order to guarantee our customers high quality and cost-effectiveness, our experienced engineers carry out the mechanical design, electrical planning and software programming themselves. We use innovative simulation tools right from the project planning stage to ensure maximum functional reliability. We also offer customer-specific programming services.

Competitive advantages through technological lead

The demands on the quality of components continue to grow – as do those on the optimization of production processes and cost savings. Our development team can meet both requirements: With sound and proven knowledge of system design, mechanical and electrical construction and control technology commissioning, right through to complete system testing. This is how we develop the right solution for every requirement.

We specialize in ECM, PECM and laser technologies. We can combine these with automation systems, cleaning technology, state-of-the-art measuring sensors, intelligent handling of data and interfaces and ease of operation for the machine user. This allows our customers to keep everything under control, from the blank to the finished end product.

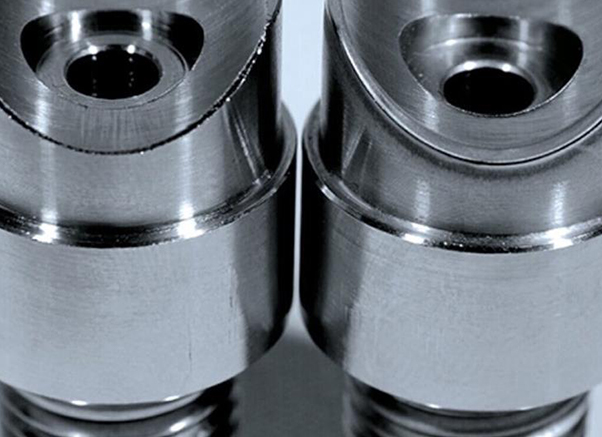

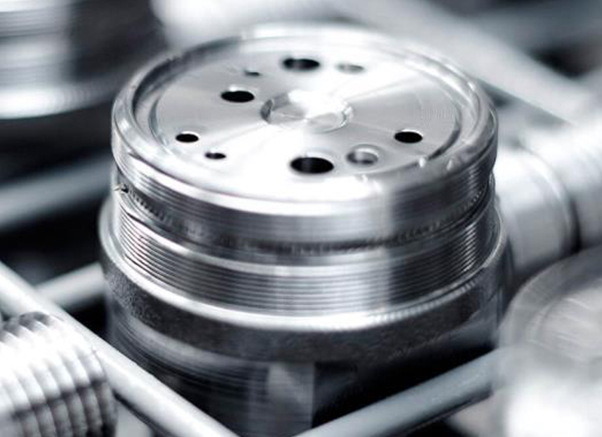

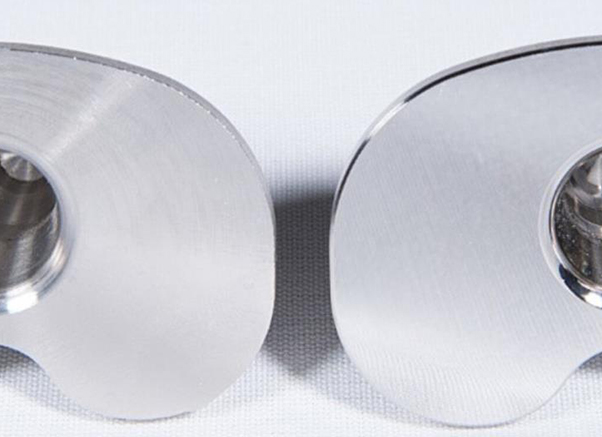

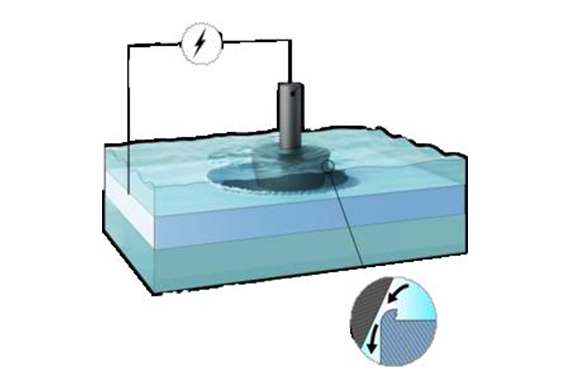

Electrochemical metal machining (ECM) is a non-contact machining process. It allows workpieces to be deburred precisely and efficiently without contact and therefore without any thermal, chemical or mechanical influence. The process is used in areas such as aerospace technology, the automotive sector and toolmaking.

The attractive entry-level model in the world of ECM deburring technology.

➤ Control system: Siemens, Beckhoff

➤ Ergonomic and clear operating concept

➤ Working area D x W: 600 x 1050 mm

➤ Generator: Up to 1,000 A at 58 V (with and without pulse function)

➤ Attractive entry-level model, even for small quantities

CAM-supported 6-axis robot for economical ECM deburring tasks, e.g. of hydraulic blocks.

➤ Effective even for small quantities, e.g. large pump housings in the oil and gas industry

➤ Precise deburring results with high repeat accuracy

➤ CAD/CAM-supported ECM machining strategy

➤ Integrated cathode changer for carrying out various deburring tasks

➤ Determination of the workpiece zero point via 3D touch probe, e.g. Renishaw OMP 40

➤ Generator: up to 3,000 A at 58 V (with and without pulse function)

ECM machines from stoba can adapt any machining process to the customer’s wishes and individual requirements, regardless of the complexity of the workpiece. Deburring, shaping, drilling or cross-drilling – our technologies offer options for every application.

ECM Deburring

ECM Molding

ECM Drilling

ECM Cross Drilling