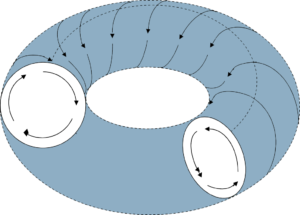

– “Random” motion processes

➢ CAVF, abrasive tumbling, drag finishing, etc.

– Can be purely abrasive (mechanical) or chemical mechanical

– Utilize “media” of some sort to impart rubbing force onto the surface of the component

– Vibratory Tubs or Bowls

– Centrifugal Disc Machines

– Drag Finishers

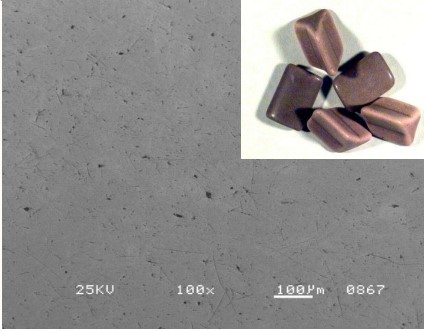

– Numerous potential compositions

➢ Abrasive or non-abrasive

➢ Ceramic, porcelain, plastic, metal

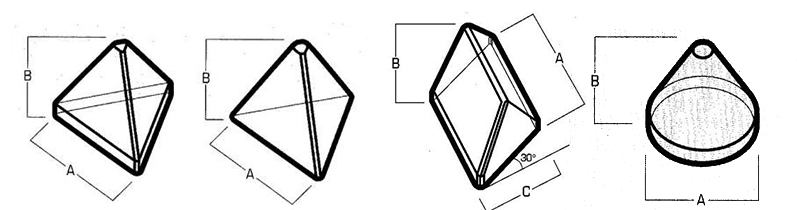

– Numerous potential shapes and sizes

➢ Cylinders, wedges, triangles, tristars, cones, tetrahedrones

➢ Angle cut or straight cut edges

➢ <1 mm in size or > 75 mm

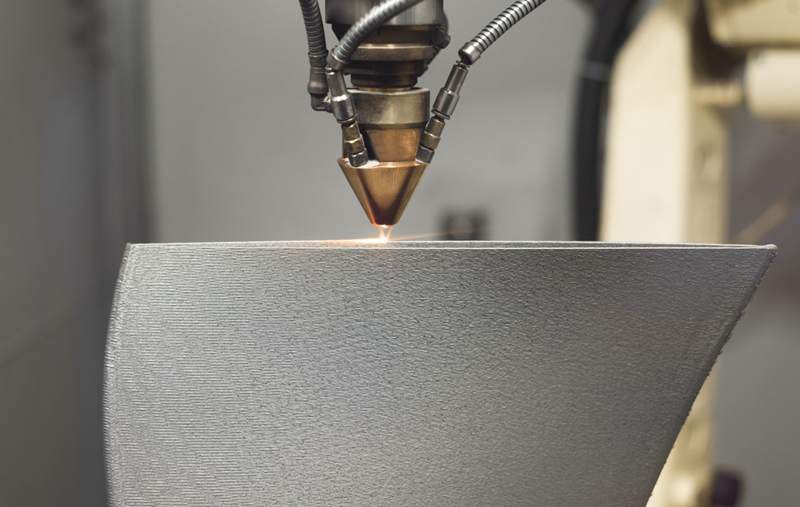

– Finishing Proces

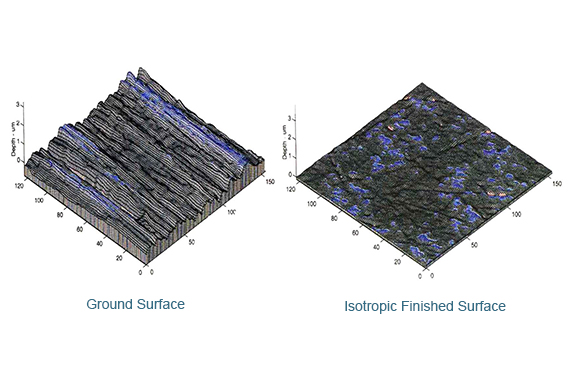

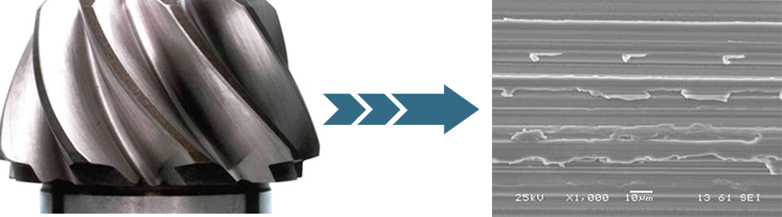

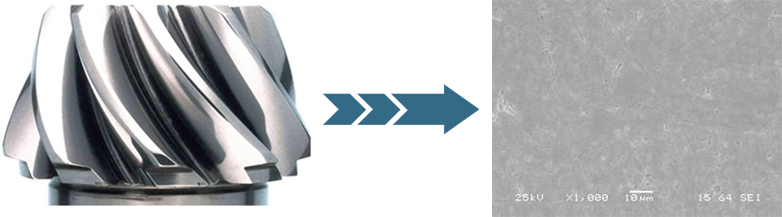

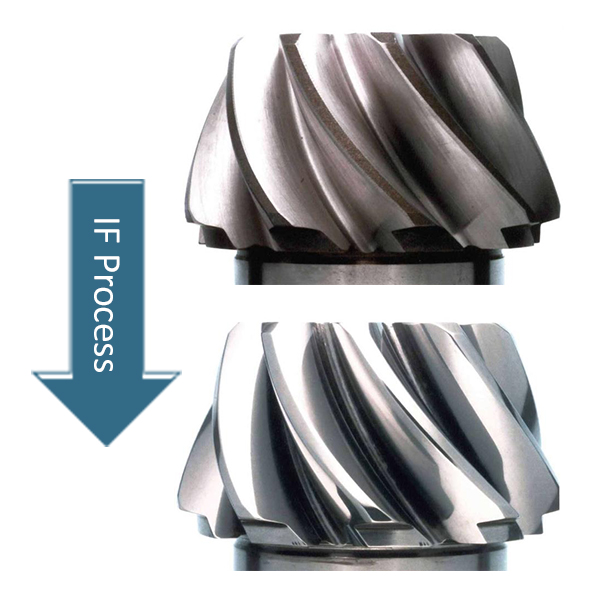

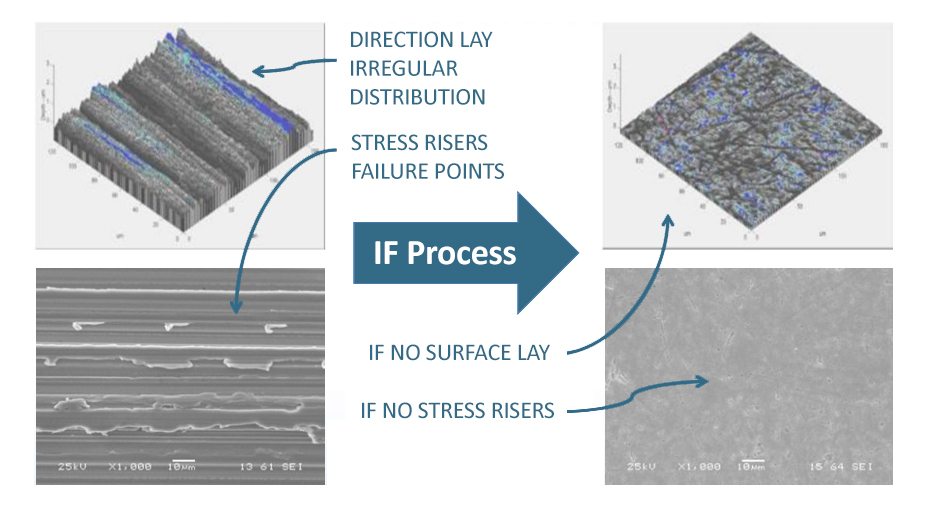

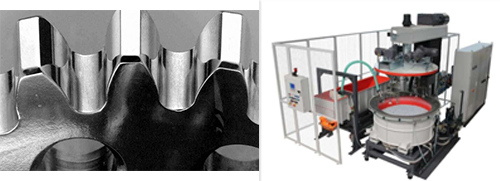

– Isotropic finish Process

➢ Creates flat surfaces

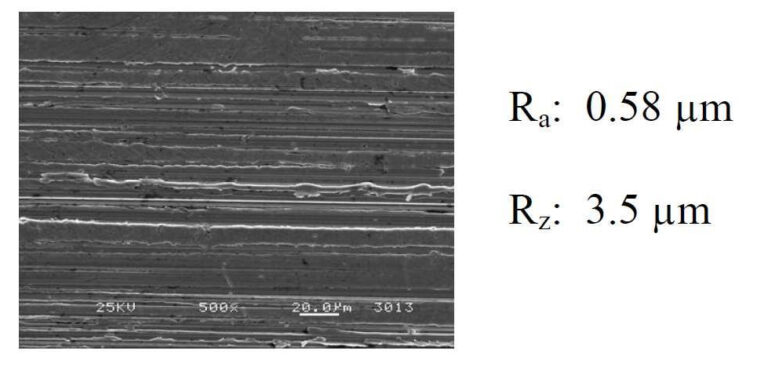

➢ For metal components

➢ Ferrous Steels (Inc. Pyrowear 53 & AISI 9310), Titanium, Inconel/Nimonic’s Nickel Alloys, Stainless Steels

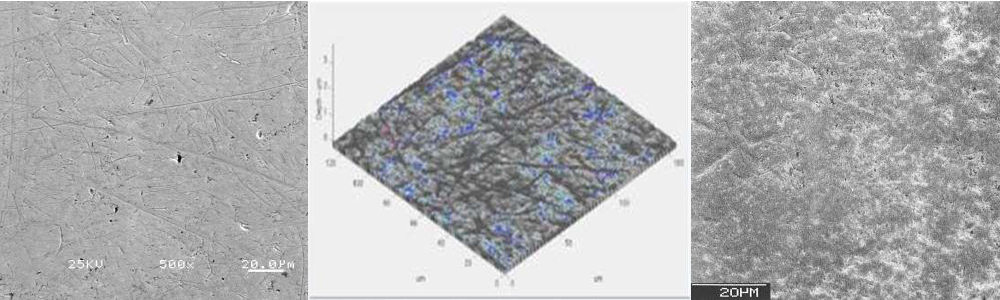

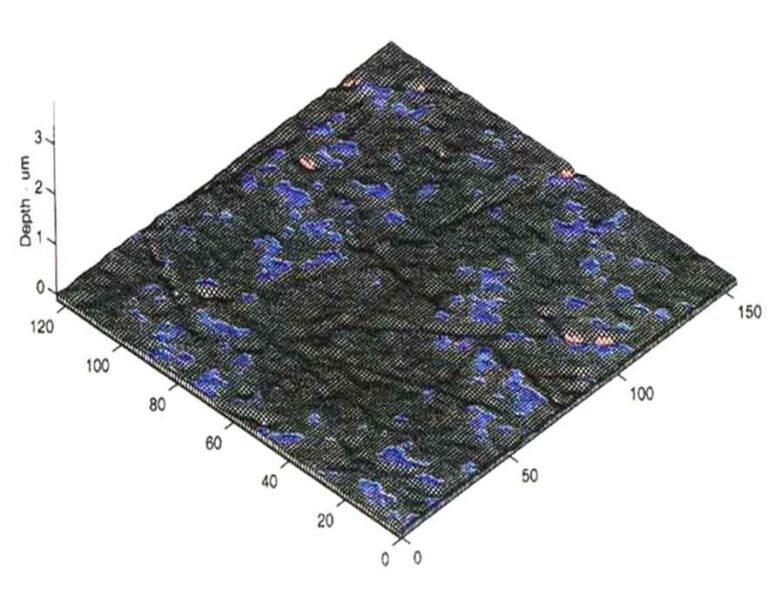

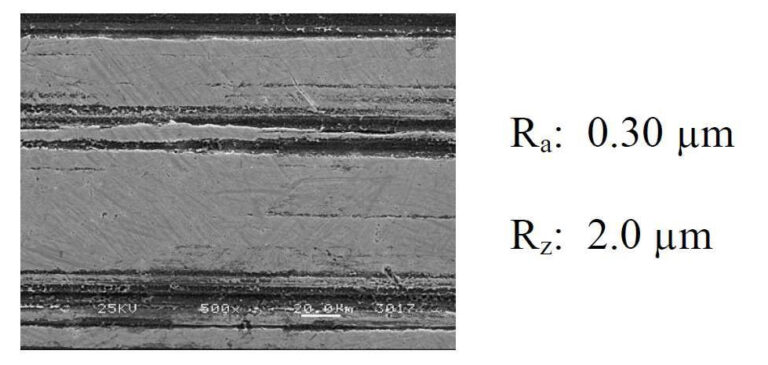

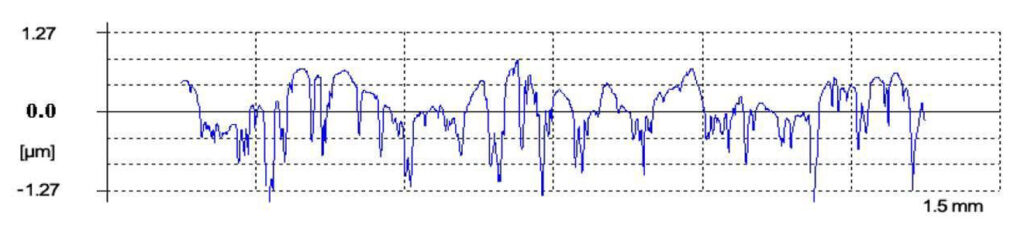

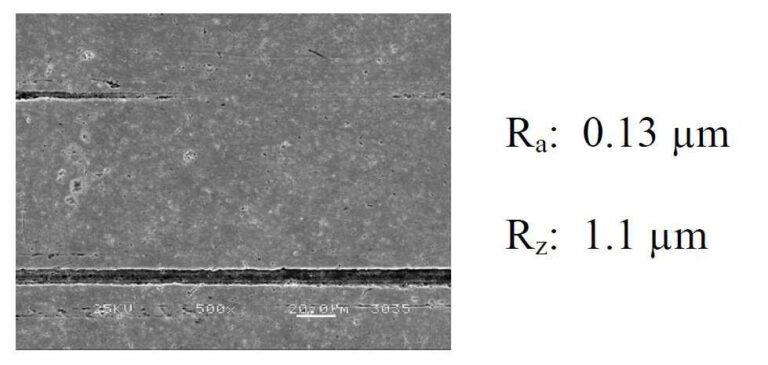

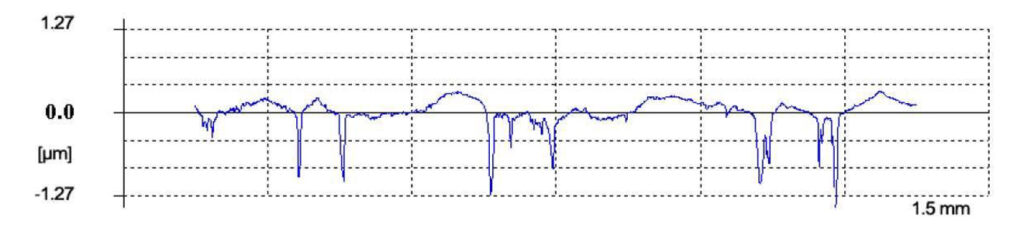

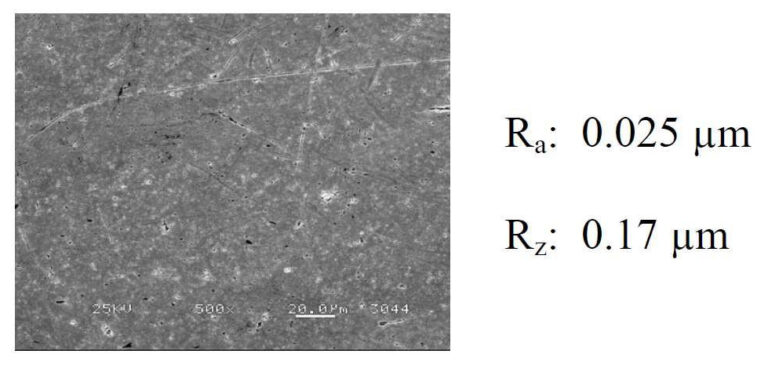

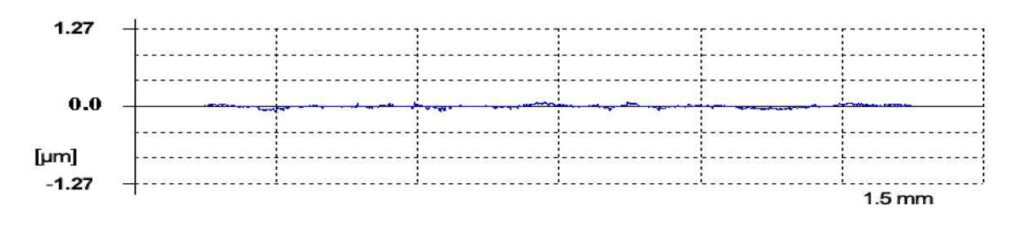

Produces Surfaces Ra <0.1µm (<0.075µm)

➢ Creates unique non-directional Micro-Texture

Maintains Geometry

➢ Chemical & mechanical process

➢ Vibratory equipment

➢ High density, non-abrasive ceramic media or media mix.

➢ Two stage chemical process

– Creates the energy for the process

➢ Off Set weights generate centrifugal

inertia

➢ Generates vibration

– Acts as reaction vessel

– Composition

– Off Set weights generate centrifugal inertia

➢ Aluminium Oxide

➢ Polyester Resin

– Can comprise of mixtures

➢ Composition, size and shape

– Removes the metal.

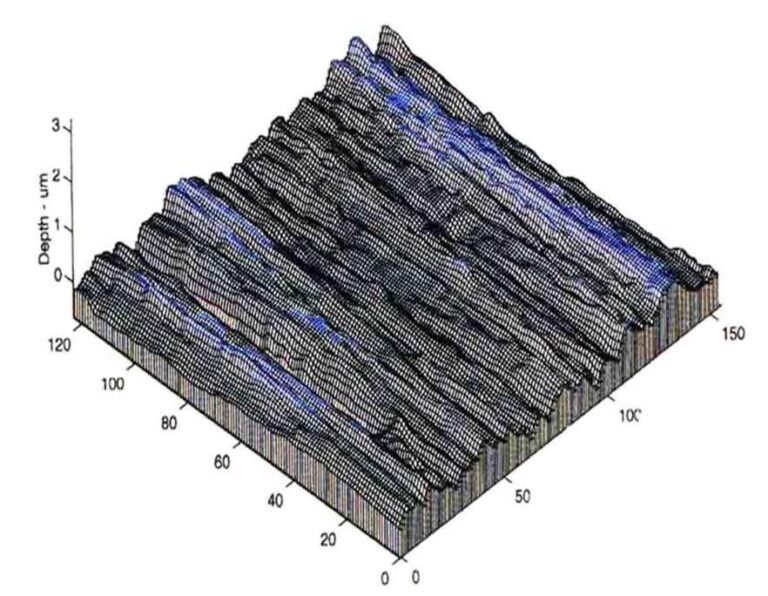

– Vibrator causes media to roll

– Media rubs over component

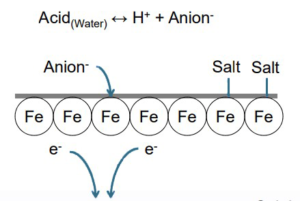

– Cannot remove metal without chemical!

– Weak Acids

– Acts as a catalyst

➢ Aluminium Oxide

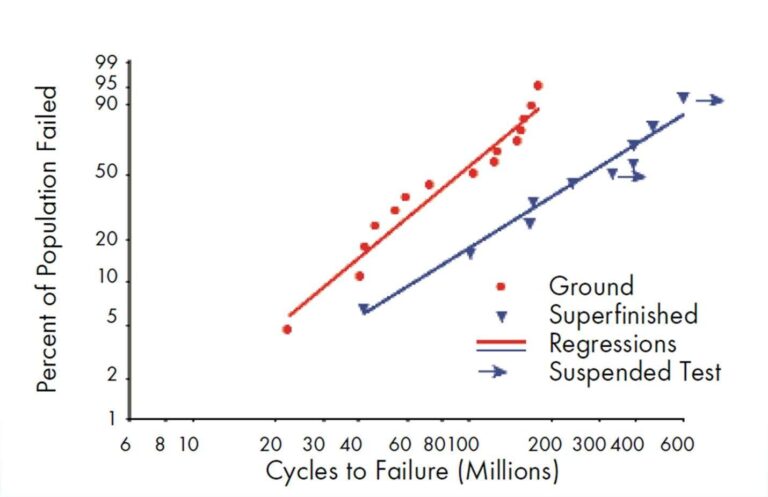

Increased Resistance to Contact Fatigue

~3x Lifecycle Increases – NASA Contact Fatigue Evaluation, X53 Spur Gears

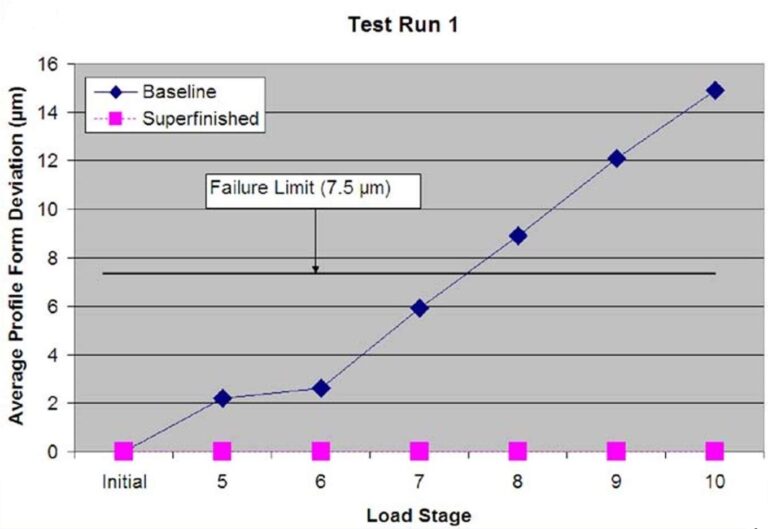

Elimination of Micropitting

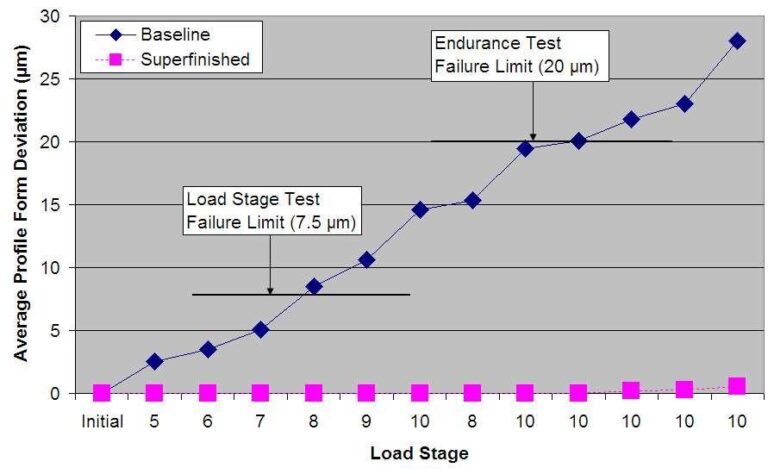

No Micropitting or Profile Form Deviation in FZG testing – University of Bochum

Increased Scuffing Resistance

~2x applied Scuffing Load without Scuffing – Cardiff University

Increased Power Density Allowable

~42% Increased Power Density Allowable – Pratt & Whitney Patent WO 2007/0646330

Reduced Friction

Elimination of Initial Break-In Cycle – Falex 3 Ball on Flat Testing

Increased Lubricant Performance

32 – 53° C Lubricant Temperature Reduction – Arizona Truck Technical Center, Hot Weather Testing

Reduced Wear

45% reduced Iron Content in Oil post 100,000 miles – New York City Taxi Fleet Study

Increased Resistance to Bending Fatigue

~5% Increase in Resistance to Bending Fatigue – University of Newcastle STBF Test

Ease of Implementation

Does not affect Component Geometry, Heat Treatment (including Nitriding), or Metallurgy

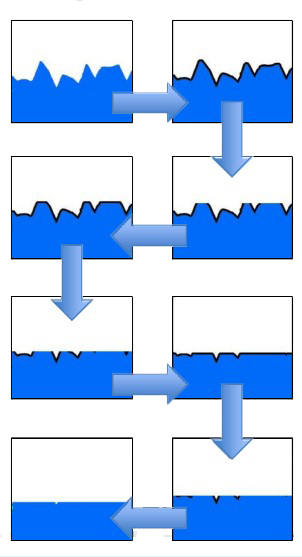

– Utilizes “active” chemistry

➢ Generates a self-limiting, soft conversion coating

➢ Lowersrequired force to refine the surface

– Mechanism:

➢ Conversion coating is removed by non-abrasive media

➢ Conversion coating reformsin the processing appartus

➢ Surface is gently refined

➢ Cycle Time ~2 – 4 hours

➢ Ra < 0.1 µm

– Lower roughness achievable pending processing parameters

➢ Applications:

– Gears, Turbine Blades, Bearings, and many more

➢ Automatable

➢ Batch Process, High Volume Capability

Applicable Metals

– Carbon Steels, Stainless Steels, Exotic Steels

➢Examples: SAE 9310, AMS 6308 (Pyrowear® 53), 300 & 400 seriesstainless steel, AMS 6517 (Ferrium® C61), AMS 6509 (Ferrium® C64)

– Nickel-based Superalloys & Titanium Alloys

Applicable Heat Treatments

– Through Hardening

– Case Carburization

– Nitriding

– Induction Hardening

Cycle Time ~5 – 10 minutes

Ra < 0.25 µm

– Lower roughness achievable pending processing parameters

Applications:

– Ring & Pinion, TransmissionGears, Engine Components

Fully Automatable

Low WIP, High Volume Capability

| Sample | Contact Stress (ksi) | Test Duration (million cycles) | Failure Mode |

| Ground/Honed Baseline | |||

| #1 | 400 | 3,6 | Pitted |

| #2 | 400 | 4.2 | Pitted |

| #3 | 400 | 3.5 | Pitted |

| Abral #1 | 400 | 44.0 | Pitted |

| Abral #2 | 425 | 1.0 | Plastic Flow |

| ISF #1 | 400 | 20.0 | No Failure |

| Same specimen and load roller tested at each stress level. | 425 | 20.0 | No Failure |

| sequentially | 450 | 22,4 | No Failure |

| Cumulative Result | 400-450 | 62.4 | No Failure |

| ISF #2 | 400 | 5.0* | No Failure |

| Same specimen and load roller tested at each stress level. | 425 | 5.0* | No Failure |

| sequentially | 450 | 20.0 | No Failure |

| Cumulative Result | 400-450 | 30.0 | No Failure |

Ra’s = Ground/Honed ~0.25 µm; ISF <0.04 µm; Abral <0.04 µm (mirror)

Ra’s = Ground 0.23 – 0.30 µm; ISF 0.05 – 0.076 µm

Ra’s = Ground 0.42 – 0.52 µm; ISF 0.07 – 0.13 µm

Ra’s = Ground 0.42 – 0.52 µm; ISF 0.07 – 0.13 µm

| Twin Disc Scuffing Testing | Isotropic Finished (Micro-Texture) | Isotropic Finished (Zink Chips) | As Ground | |||||

| Test | 1 | 2 | 3 | 1 | 2 | 1 | 2 | 3 |

| Scuffing Load @ Failure (N) | 4150* | 4150* | 4150* | 4150 | 3452 | 2320 | 2320 | 2320 |

| Maximum Bulk Temperature of Fast Disc (°C) | 187 | Error | 168 | 201 | 199 | 189 | 197 | 204 |

| Maximum Bulk Temperature of Slow Disc (°C) | 154 | 152 | 142 | 153 | 144 | 190 | 176 | 178 |

| Average Bulk Temperature of Discs (C) | 170 | n/a | 155 | 177 | 171.5 | 189.5 | 186.5 | 191 |

Ra’s = ISF (Micro-Texture) 0.0285 – 0.0366µm, Zinc Chips <0.1 µm, Ground 0.4 µm

*No scuffing occurred even after a 30 minute endurance cycle at maximum load

| Twin Disc Scuffing Testing | Isotropic Finished (Micro-Texture) | Isotropic Finished (Mirror-Polished) | |||

| Test | 1 | 2 | 3 | 1 | 2 |

| Scuffing Load @ Failure (N) | 4150* | 4150* | 4150* | 3450 | 3450 |

| Maximum Bulk Temperature of Fast Disc (°C) | 187 | Error | 168 | 152 | 149 |

| Maximum Bulk Temperature of Slow Disc (°C) | 154 | 152 | 142 | 125 | 124 |

| Average Bulk Temperature of Discs (C) | 170 | n/a | 155 | 138 | 136 |

Ra’s = ISF (Micro-Texture) 0.0285 – 0.0366 µm, Mirror-Polished 0.0156– 0.0193 µm

| Test Specimen | Contact Stress (ksi) | Test Duration (minutes) | Result |

| SAE 9310H | 400 | 30 | No Failure |

Ra’s = ISF <0.04 µm Specimen >30 million cycles prior to testing

– Low Oil Pressure

➢10 – 15 psig below specified minimum

– High Temperature Testing

➢15 – 20 ⁰F above specified maximum

– Both = 30 minute tests@ 550 hp & 6,000 RPM

No Scoring or Contact Fatigue

from Extreme Condition Testing

Ra’s = ISF (Micro-Texture) 0.0381 – 0.157 µm, AverageRa = 0.091 µm

– 3 gearbox designs (bearing variations) subjected to “loss-of lubricant” testing

➢ PEEK Bearing Cages

➢ Steel Bearing Cages with Heat Pipes

➢Steel Bearing Cages without Heat Pipes

– ISF Process was used on all gears

➢Publicly acknowledgedat presentation

– PEEK Bearing Cages

➢ PEEK Melted at 40 minutes of operation

➢ Some signs of scuffing/discoloration

➢ Gears showed no signs of surface damage based on MPI

– Steel Bearing Cages with Heat Pipes

➢ Test suspended at 73 minutes due to rapid temperature increases

➢ Evidence of scuffing, but overall gears in good condition

– Steel Bearing Cages without Heat Pipes

➢ Test suspended at 85 minutes due to rapid temperature increases

➢ Evidence of scuffing, but overall gears in good condition