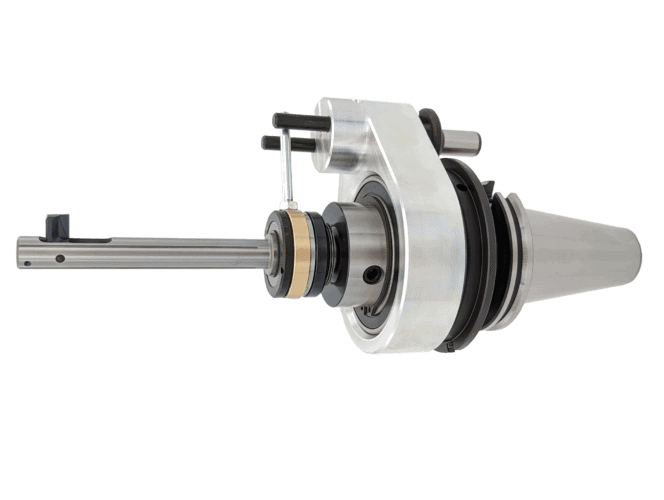

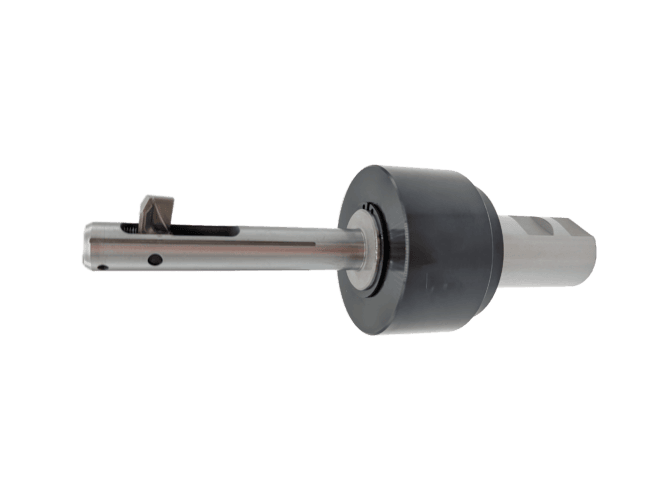

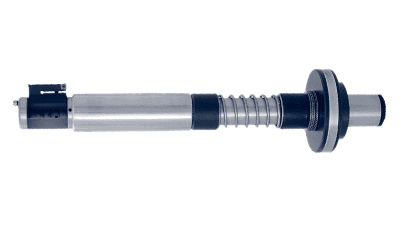

A lot of components in the industry have counter bores or spot faces on the front as well as the back surfaces of a component. Most companies use different setups to machine the two surface. Some companies make a special tool which requires interpolation and is thus inefficient. Our specialized plunge type tools allow you to create counter bores and spot face on the front and back surfaces in no time.

What sets the Autofacer apart from other back spot-facing tools?

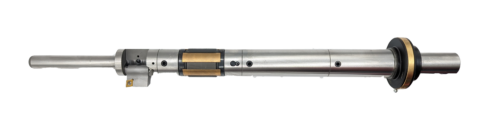

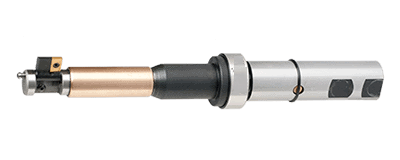

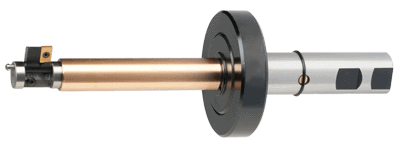

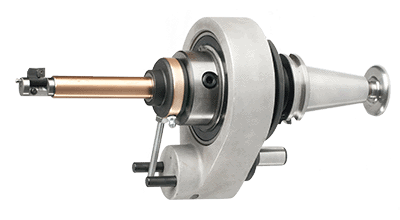

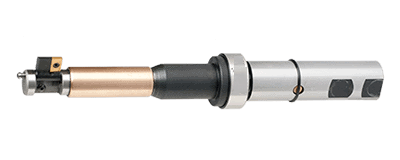

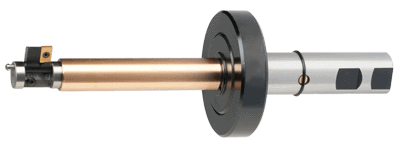

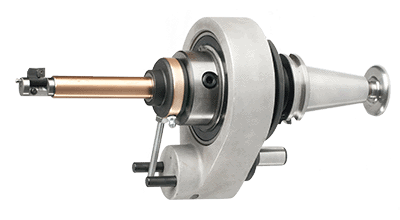

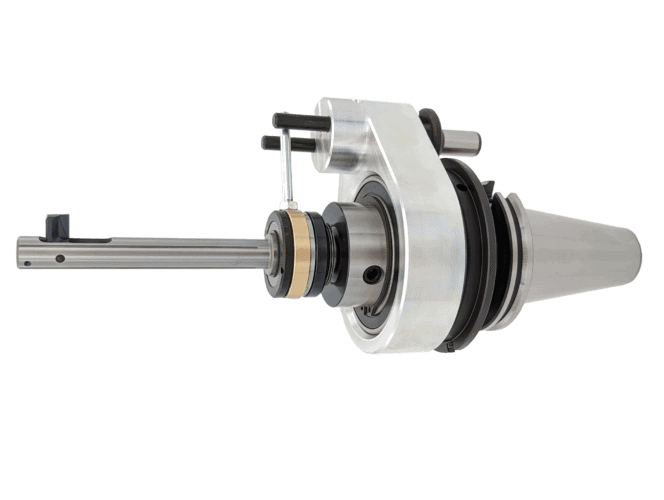

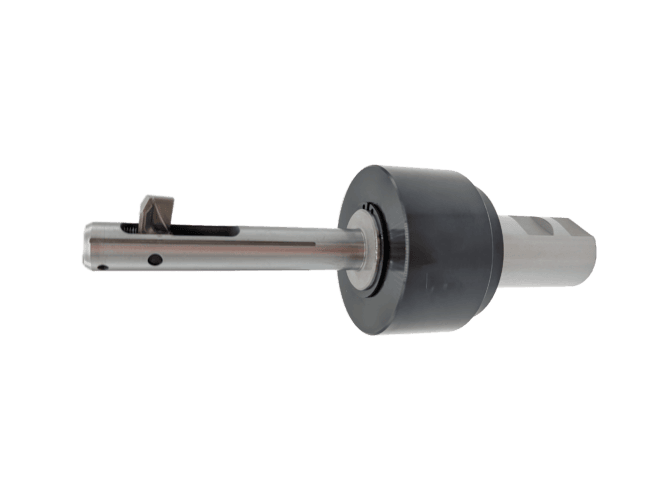

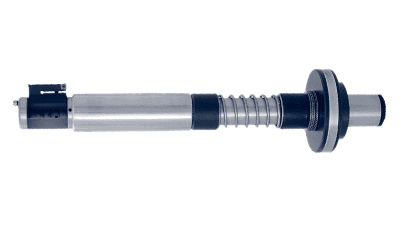

The Autofacer is an ingenious automatic back counterboring tool that allows a machinist to reach through a hole and machine a circular feature* on the back side of the part automatically. This is accomplished by folding the cutting blade into the shaft of the tool body allowing the tool to pass into the part. Once the tool has entered the part, the cutting blade is mechanically opened and cutting may begin.

Obtuz is the OEM of the Autofacer since 1968 and we continue to be the world leader in automatic back spotfacing and back counter boring tools.

* Circular features might include a spot face, counterbore, countersink, chamfer, spherical radius, or some combination thereof.

How it Works

Advantages

How it Works

Advantages

How it Works

Advantages

How it Works

Advantages

How it Works

Advantages

How it Works

Advantages

How it Works

Advantages

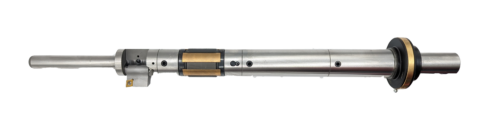

Specialized Autofacers for Machining Seat Pockets and Clearance Bores on Subsea Gate Valves

How it Works

Advantages

How it Works

Advantages

How it Works

Advantages

How it Works

Advantages

How it Works

Advantages

How it Works

Advantages

How it Works

Advantages

Specialized Autofacers for Machining Seat Pockets and Clearance Bores on Subsea Gate Valves