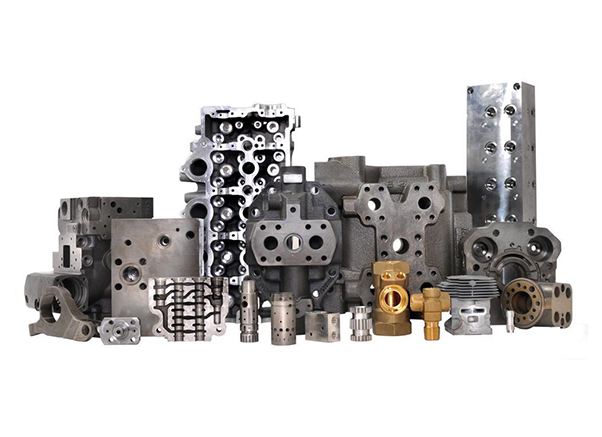

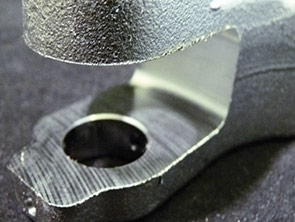

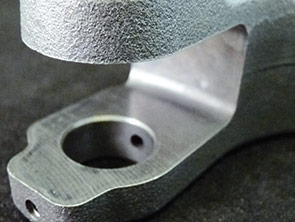

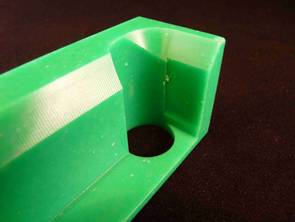

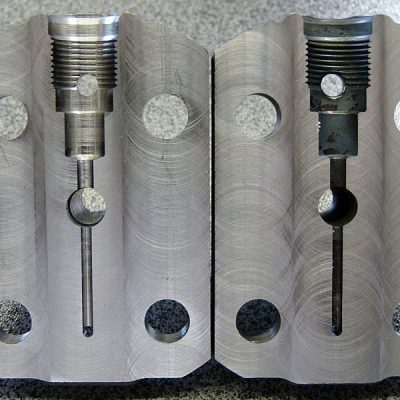

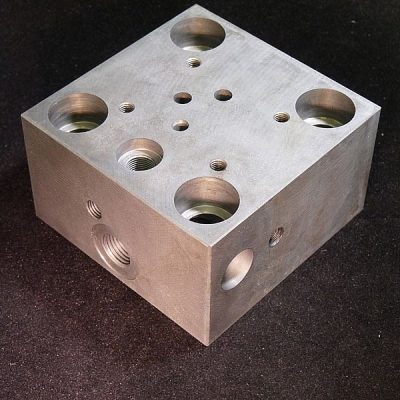

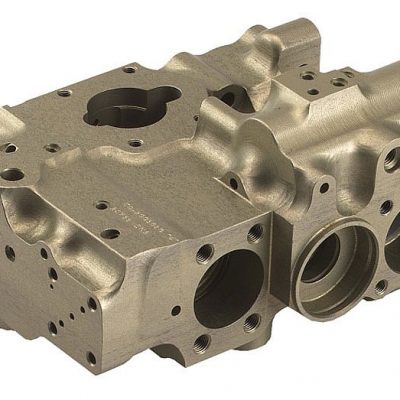

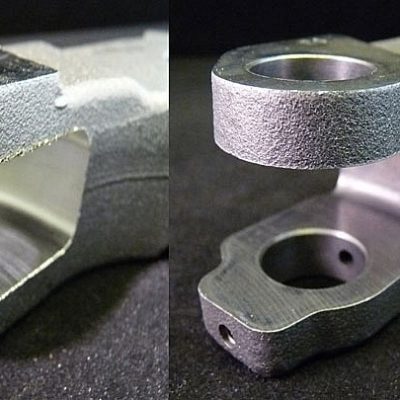

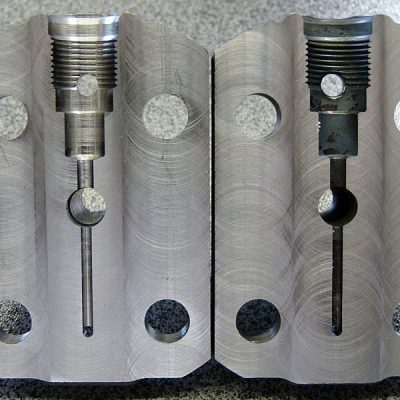

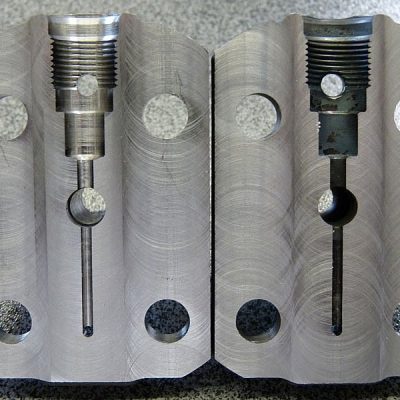

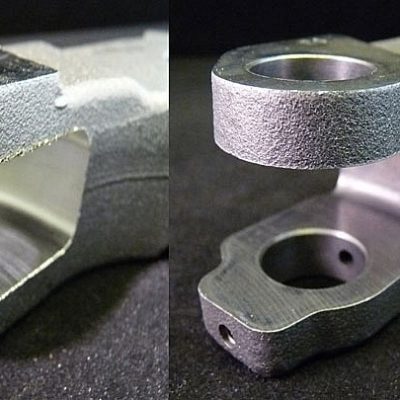

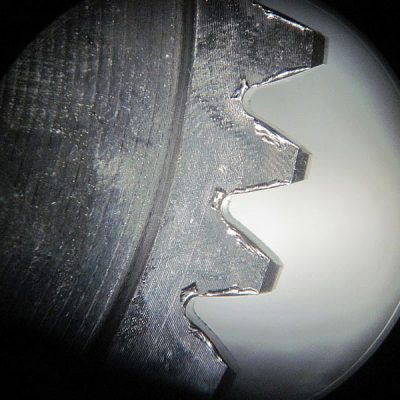

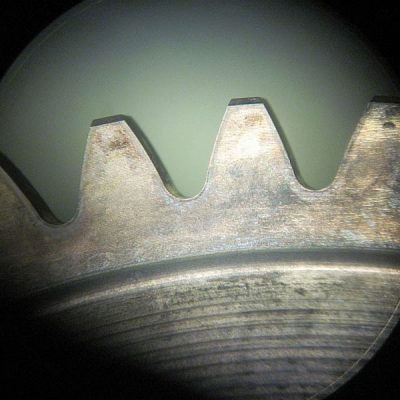

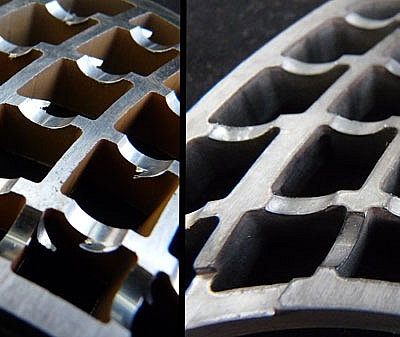

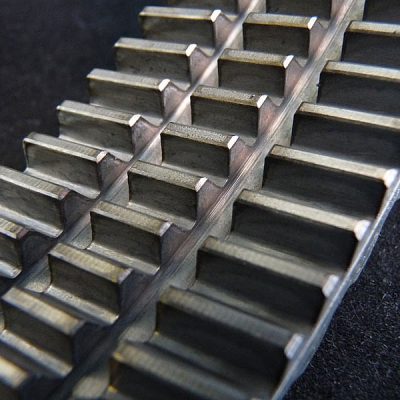

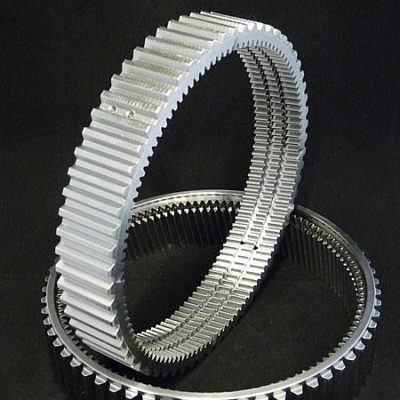

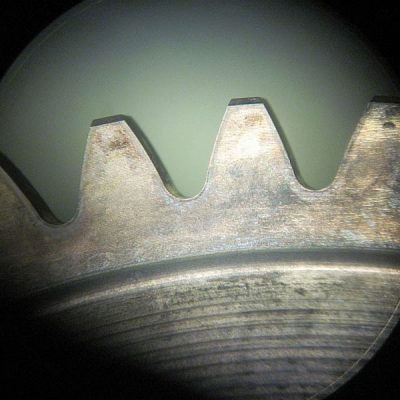

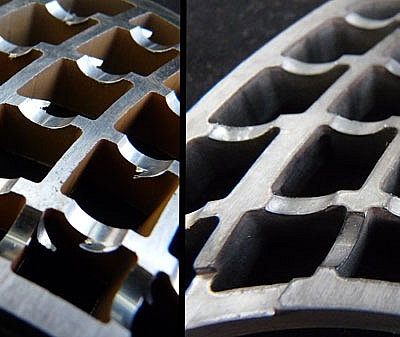

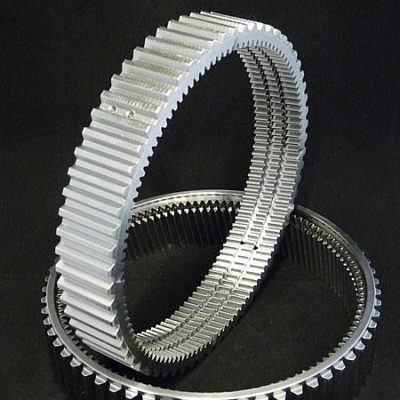

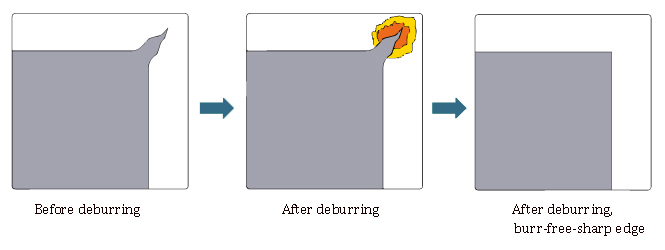

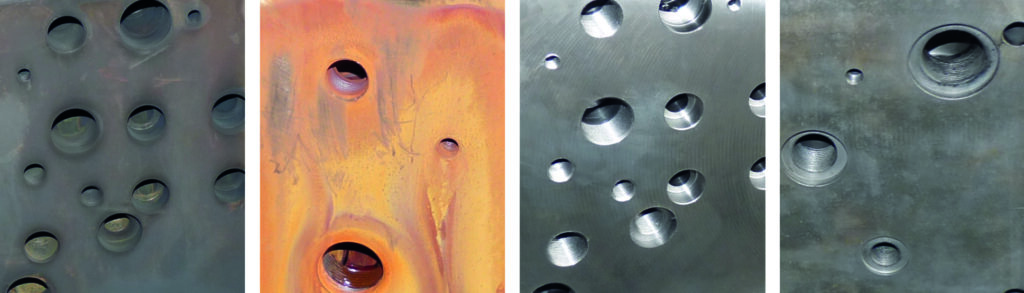

In the before and after comparison, the differences and thus also the advantages over other processes are clearly visible. Thermal deburring delivers reliable and reproducible results in a matter of seconds. The examples listed show components from different industries and different materials.

The process can be used on the following components:

In the before and after comparison, the differences and thus also the advantages over other processes are clearly visible. Thermal deburring delivers reliable and reproducible results in a matter of seconds. The examples listed show components from different industries and different materials.

| METHOD | HIGH PRESSURE WATER JET DEBURRING |

|---|---|

| machine | HDW machine with 750 bar |

| investment | from 300,000 € |

| Connection |

|

| Cycle time | 2.5 minutes per component |

| Capacity (pieces/h) | 24 pieces |

| Energy costs |

|

| Advantages |

|

| Disadvantages |

|

| METHOD | THERMAL DEBURRING |

|---|---|

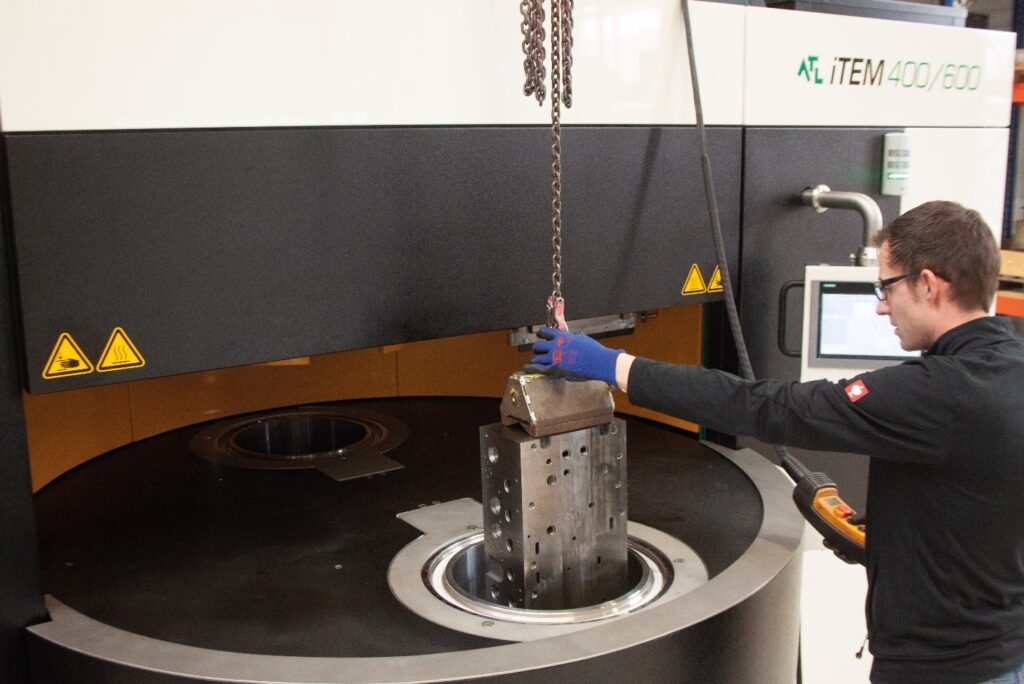

| machine | iTEM320 SC |

| investment | from € 305,000 |

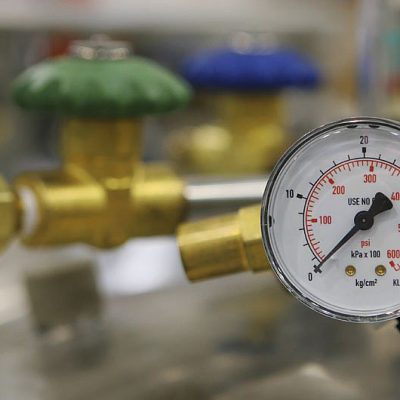

| Connection | › Electricity › Methane (CH 4 ) or natural gas › Oxygen |

| Cycle time | 10 components in 90 seconds |

| Capacity (pieces/h) | 400 pieces |

| Energy costs |

|

| Advantages |

|

| Disadvantages |

|

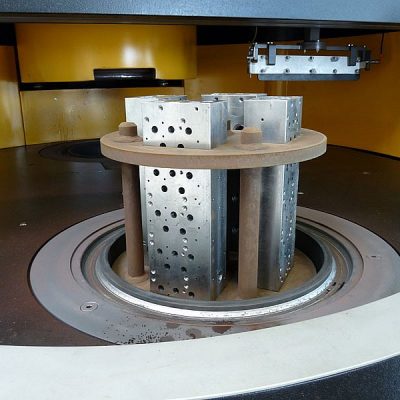

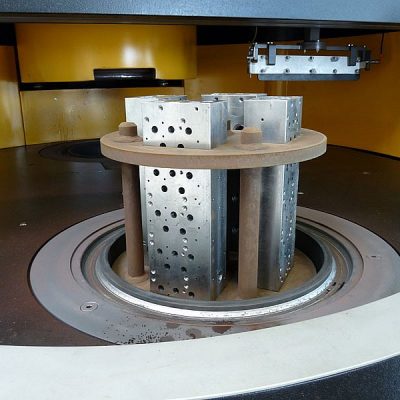

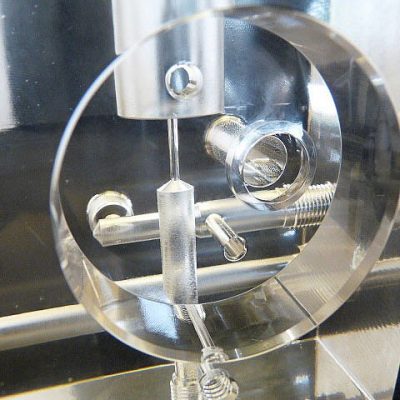

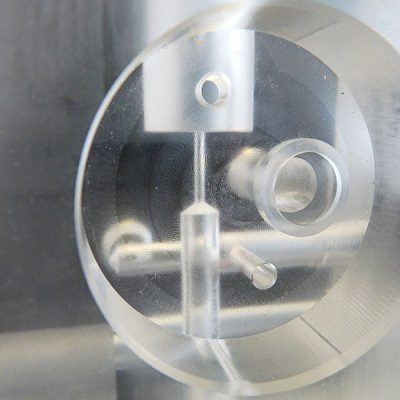

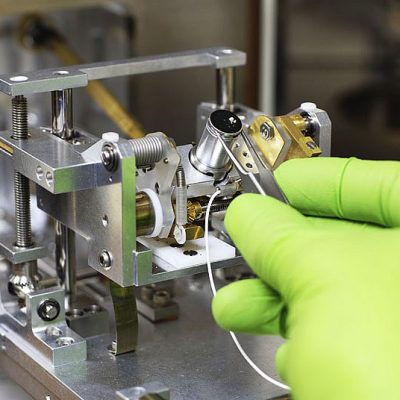

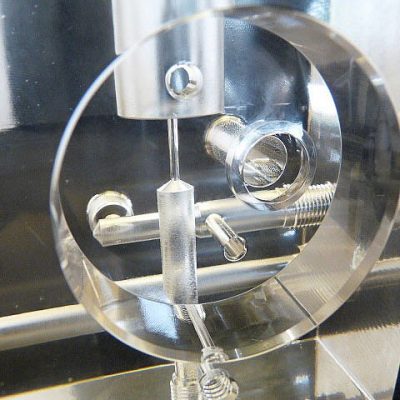

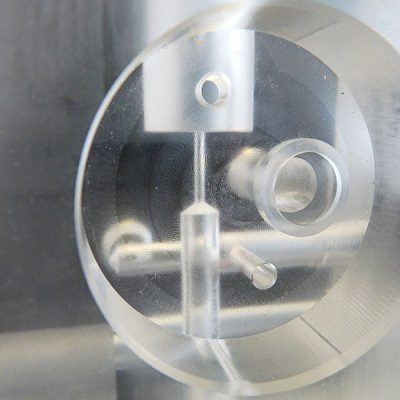

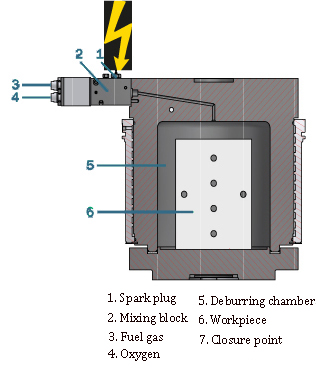

For this purpose, the workpieces are placed in a bell-shaped deburring chamber, which is hydraulically closed using a locking plate. A precisely defined mixture of fuel gas and oxygen is fed into the deburring chamber via a gas dosing system and ignited. The subsequent combustion produces temperatures of 2,500-3,300 °C. The burr to be removed reaches its ignition temperature and reacts with the excess oxygen in the deburring chamber. This leads to complete combustion of the burrs within 20 ms.

A wide variety of metallic materials and all thermoplastics such as PA, PE, PTFE, PUR and PMMA can be processed, as well as injection-molded parts without glass fiber content. The cycle time for thermal deburring is less than two minutes in total.

➤ Uniform deburring of all external and internal burrs in one operation, process reliability

➤ Process does not affect the surface structure (in the case of plastic parts, the surface is smoothed)

➤ Deburring result from sharp-edged/burr-free to slight edge rounding à depending on the material

➤ Unmatched cleanliness and fast cycle times

➤ Suitable for high volumes, while keeping energy costs low

➤ No wearing tools

➤ Simple workpiece holders

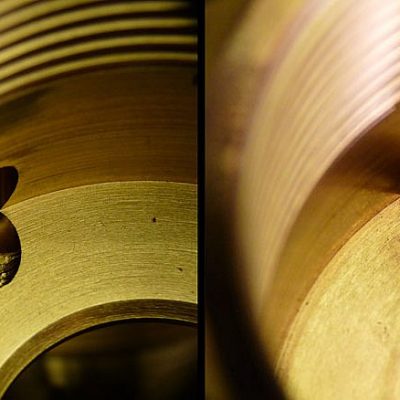

The colors of thermal deburring on ferrous materials are derived from the different process stages.

Washing the temped component is – depending on the material – an important part of the post-treatment

In principle, metals that are susceptible to oxidation can be deburred. However, there are restrictions for commercially available materials in the following cases:

➤ Magnesium, as this material is prone to uncontrolled, further combustion due to its low ignition temperature, as well as its melting and boiling point

➤ Titanium, due to its very high boiling point (3,535 °C)

➤ The same applies to high-temperature materials for aerospace engineering (e.g. zirconium)

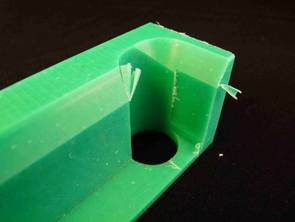

As a rule, all thermoplastics can be processed. However, the burr is melted off and not oxidized. Only pure thermoplastics are suitable. Plastics with a glass fiber content are only suitable to a limited extent.

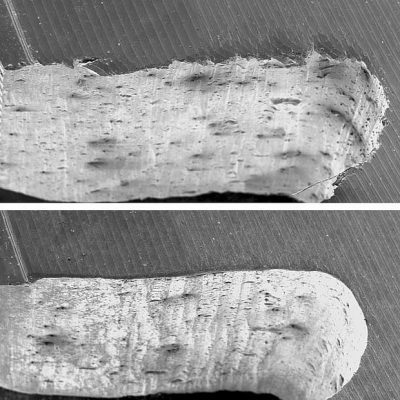

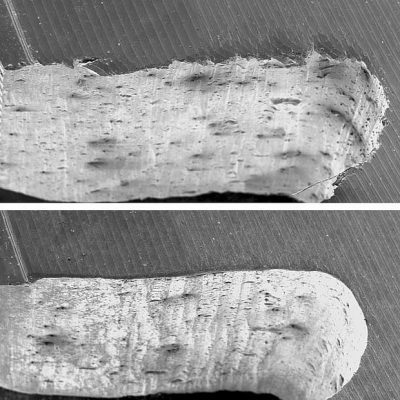

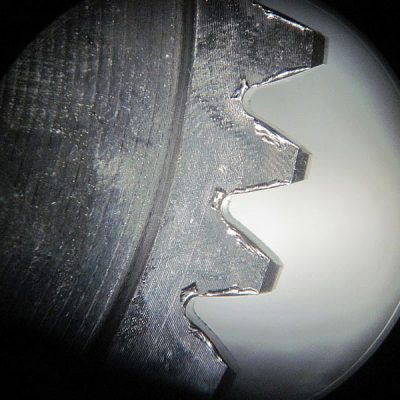

When deburring, the burr melts away slightly more than the glass fibers, so that the edge, seen microscopically, looks jagged. The roughness of the burnt edge can also be felt with the fingers. Duroplasts, on the other hand, cannot withstand the explosion pressure due to their brittleness and burst.

The application area of “thermal-chemical deburring” is limited by various factors. The material from which the components are made and the size of the burrs limit the possible uses of the process. The thermal load on the workpiece to be deburred depends on the required deburring quality; it must usually not exceed certain limits.

The burr formation must be appropriate to the material.

This means that iron materials, which have poor thermal conductivity, may have a stronger burr formation than light metals, where the exact opposite applies.

The material must be oxidizable. Exception: plastic, in which case the burr is melted off.

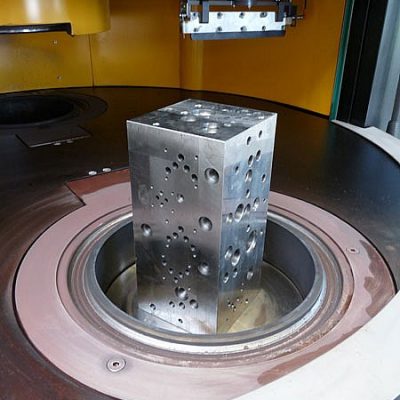

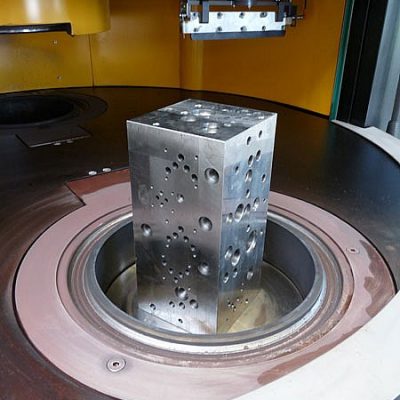

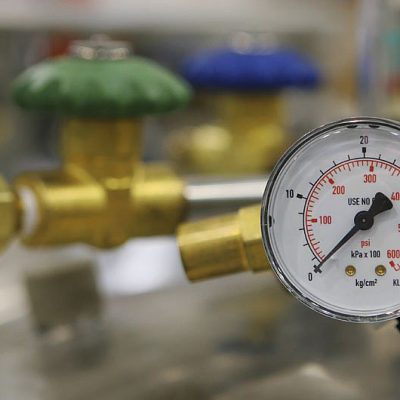

The workpiece may only be as large as fits into the largest deburring chamber currently available. Thanks to the variable chamber dimensions of the iTEM thermal deburring systems, components of a wide range of sizes can be processed. It is not just the standard series that offer a certain degree of flexibility. Special deburring chambers can often be developed for components that have special requirements due to their dimensions. These special machines then enable the thermal deburring of, for example, heating circuit manifolds from the sanitary sector or long components from the automotive industry.

The machine can be supplied with fuel gas and oxygen in various ways. There are three types of supply:

Since the burned-off material is deposited on the entire component surface in the form of iron oxide after the TEM process, further processing of the workpieces is usually necessary. Exceptions exist if the components are subsequently galvanized, hardened or nitrided.

For steel and cast parts, a suitable washing technique should be used promptly – between 1 and 3 days. If the iron oxide remains on the treated surfaces for a longer period of time, rust marks can form. The following cleaning techniques can be used:

1. pH-neutral cleaning with ultrasound support

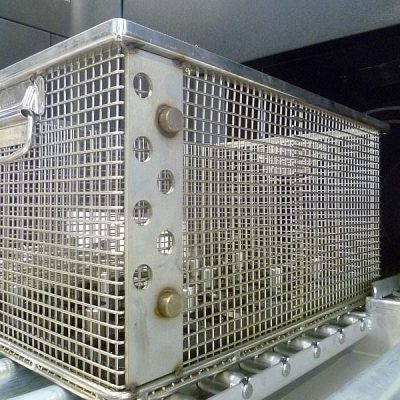

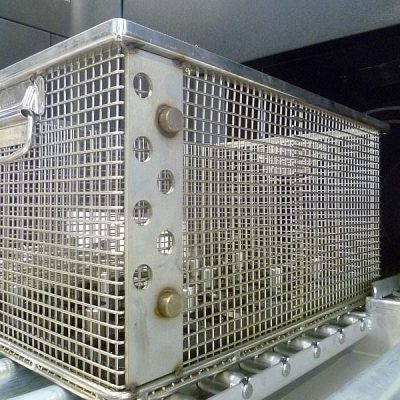

In so-called single-chamber systems, the components are placed in baskets and cleaned in a pH-neutral bath using ultrasound, and are also sprayed with high pressure (16-18 bar). The workpieces are then passivated and dried in a vacuum. This technology has become established worldwide in recent years, with the following being particularly noteworthy:

2. Acid pickling The components are treated in a bath of phosphoric and sulphuric acid. This method is effective, but also has some disadvantages:

For workpieces made of aluminum and zinc die-casting, the post-treatment depends on the application of the component. Many components are ready for installation after thermal deburring. However, if the customer requires a low residual dirt content, such as with pneumatic valves, cleaning is essential.

The TEM process is one of the fastest and most cost-effective removal processes, achieving high quality and repeatability. Burrs, adhering particles and deposits are reliably removed. The processing of a complex component or many smaller components is possible after a short changeover time.

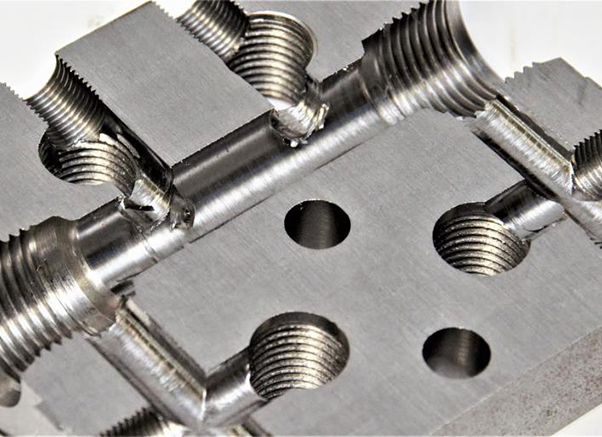

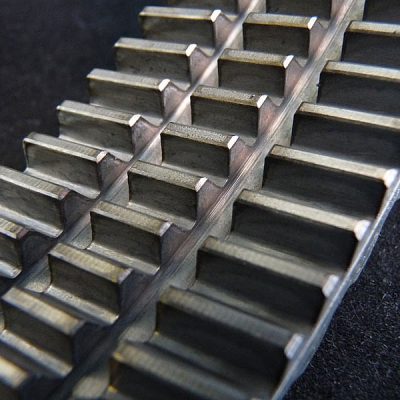

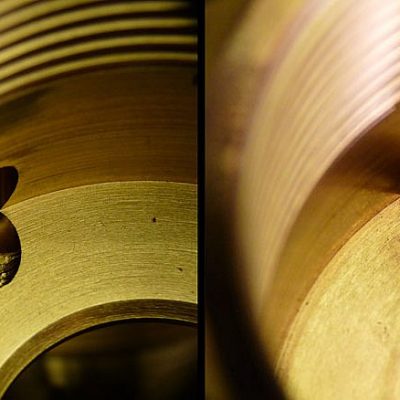

Thermal deburring produces a clean, tight and easy-to-install thread. The leading edge, which often breaks or lifts off and damages seals, is deburred. The threads are neither rounded, flattened nor affected on the surfaces.

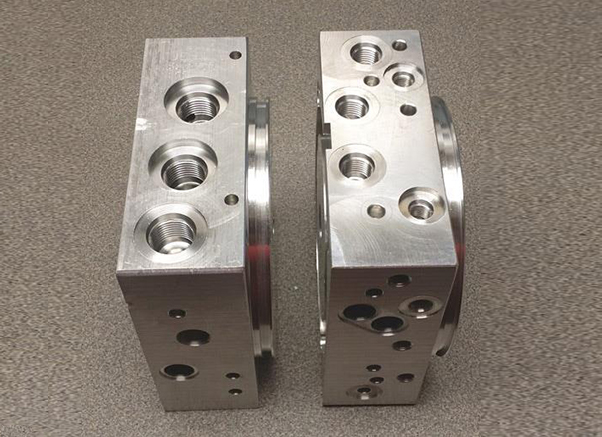

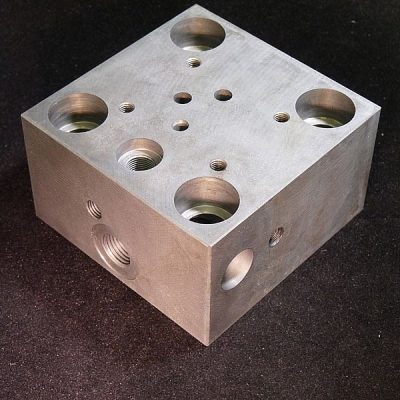

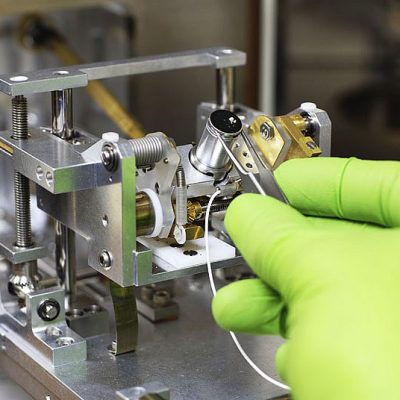

With smaller components, the process reaction can cause the workpieces to collide with one another and become damaged. To avoid this, the components are held in fixtures and fixed in place. Larger components, such as hydraulic blocks, can usually be processed without a fixing device.

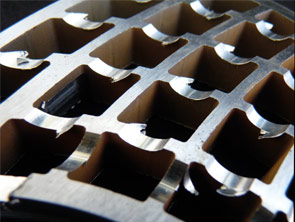

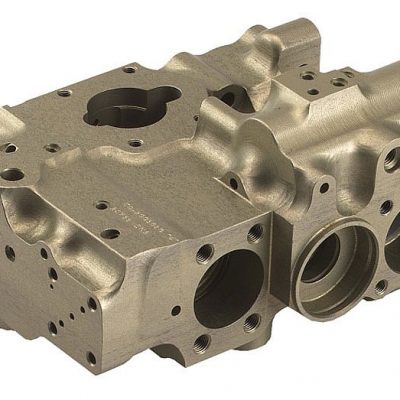

The primary application area is cast and turned parts as well as distribution blocks. The process can achieve considerable savings on bodies for hydraulic and pneumatic valves, as well as cast parts with internal bore intersections. In the case of zinc die-cast workpieces, machining and casting burrs are removed simultaneously. Furthermore, precise turned and milled parts can be deburred in a matter of seconds using TEM.

As a rule, the components must be further treated. After thermal deburring, the burnt-off material settles on the material surface in the form of iron oxide. Since it is both visually and functionally disruptive, it must be removed. This can only be dispensed with if the components are subsequently subjected to galvanic treatment.

The energy source of the process is gas, which is evenly distributed within the deburring chamber and the workpiece. No opening is too small for gas to penetrate, especially under pressure. This means that every machining burr, every edge, every shaped burr and every particle is surrounded by gas.

The success of deburring depends on the thermal conductivity and the specific heat absorption of the metals. Iron materials, but also metals such as aluminum and zinc alloys, can be processed particularly well. Stainless steel can also be thermally deburred, but with restrictions.

Thermal deburring of plastics is basically possible. Due to low gas pressures and process temperatures, as well as low melting points of thermoplastics, the process requires special parameters for low energy densities. ATL’s thermal deburring machines are equipped with high-quality control and regulation technology, so the processing parameters for thermoplastics can be set sensitively and reproducibly.

Steel components reach temperatures in the range of 130-150 °C, aluminum components reach around 60-90 °C.

The fuel gases that can be used for the TEM process are methane, hydrogen and natural gas. For the latter, a natural gas compressor is also required.

Thermal deburring is a non-selective process. Although slight edge rounding can be achieved, targeted control of edges is not possible.

The process can be adjusted to deburr the edges while keeping them sharp.

Small holes are deburred just as reliably as other areas.